Here is an essay on ‘Sericulture’ for class 11 and 12. Find paragraphs, long and short essays on ‘Sericulture’ especially written for school and college students.

Essay on Sericulture

Essay Contents:

- Essay on the Introduction to Sericulture

- Essay on the Types of Silk

- Essay on the Physical and Chemical Properties of Silk

- Essay on the Science of Sericulture

- Essay on the Silk Production in India

ADVERTISEMENTS:

Essay # 1. Introduction to Sericulture:

Silk is the protein secreted by the larvae of certain Lepidopteran moths. It is fibrous in nature, and widely used for the manufacture of art clothes. The silk is derived from silk moths mainly belonging to Bombycidae and Saturuidae families of lepidoptera.

The origin of silk industry is a controversial topic. According to one source the origin is from India during 200 B.C. (Himalayan region). Whereas another view holds that it originated from China. The knowledge of silk production spread for and wide by the passage of time. Today many Western nations along with Japan, Russia, and Persia. Africa and India are practicing the culture and production of silk.

Sericulture is the art of rearing silk worms under artificial or domesticated conditions and extraction of the silk fiber from their cocoon.

ADVERTISEMENTS:

The moths belonging to two major families, Bombycidae and Saturnidae of Lepidoptera group of insects produce commercial silk in India Based on the quality and lusture of the silk fibers 4 types of silk are produced by die different forms of silk secreting moths. The main species of silk secreting moths are Bombyx sp. Attacus sp. and Anthracea sps.

Essay # 2. Types of Silk:

Silk industry in India is supported by different types of silk worms. The qualities of the silk produced by these worms vary. Though there are different types of silk worms, the commercial silk are of 4 types.

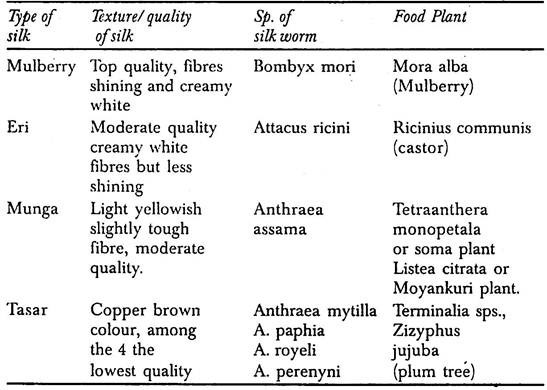

Information’s regarding the silk varieties; the respective silk worms and their food plant are given in the following table:

Essay # 3. Physical and Chemical Properties of Silk:

The silk fibre quality and quantity depends on the size and robustness of the cocoon. It is estimated that on an average a cocoon gives silk filament of 600-1200 m. To produce 1 lb. of raw silk about 2300-2600 cocoons are required. In terms of weight about 11 kg., of cocoon’ may yield 1 kg., of raw commercial silk and 1.5 kg of waste silk for spinning. The thickness of the silk filament produced by Bombyx mori varies from 0.018 mm.

The filaments have great tensile strength (tensile strength of silk 64,000 lb/ssq. Inch and that of iron 90,000 Ib/sq. inch) and good elasticity (the silk fibre can stretch one fifth of its original length). These two properties of silk owe much of its excellence as a textile material.

Silk filaments are formed of an inner core of material called fibroin covered by another substance called sericin. Fibroin constitutes about 70-80% of the filament. It is an amphoteric colloidal protein of formula C15 H22 N5 O6. Fibroin when heated burns and gives the smell of burned feather. This property is used to distinguish genuine silk from artificial silk. Sericin is also a protein of albuminous nature.

Uses of Silk:

Silk is used mainly in the textile industry for manufacturing garments, especially in the making of women’s hosiery. Due to the high investment required in the collection and production of silk, use of silk textiles has become rather a status symbol. Silk is also used in the manufacture of cartridge bags, telephone cable insulations, for dyeing, screen printing etc.

Essay # 4. Science of Sericulture:

Commercial sericulture is carried out in large scale in many states mostly under Government observation. Sericulture is the art of rearing of silk worms under artificial or domesticated conditions, their feeding, and cocoon formulation.

Maintenance and recovery of cocoons, and extraction of silk fibres. An essential part of sericulture is the cultivation of host trees of the respective silk worm to ensure continuous supply of natural food for the silk worm. A trial in substituting artificial food for plant food has turned out to be futile.

ADVERTISEMENTS:

For convenience the methodology of sericulture is discussed under five headings:

1. Collection of eggs.

2. Incubation of eggs.

3. Rearing of larvae.

4. Recovery of cocoons.

5. Reeling of cocoons.

1. Collection of Eggs:

Ripe cocoons are selected for mating and production of eggs. The cocoon meant for raising adult moths are collected, threaded together and hung from roof to within a foot of the ground. Earlier examinations are made to assess the health of the cocoon. Unhealthy or ill formed cocoons are rejected.

In the “seed station” can be observed many long strings of cocoon masses suspended on strings. Within the prescribed period the moths emerge and; they mate each other, (female moths can be identified by studying the external features). The mated females are collected in disinfected linen bags. The bags are hung on the ceiling with their mouths tied. Within a few hours the female moth lays her eggs inside the bag and dies.

This procedure carried out for large-scale production of eggs or seeds (commercial term). The eggs are collected and washed repeatedly in distilled water to remove dirt’s excreta. The eggs are examined under the microscope at regular intervals for infections. It is estimated that the weight proportion of egg and silk fibre produced is in the ratio 1.250 i.e. to produce 250 lbs of silk. 1 lb of egg must be hatched and reared. The healthy and viable mass of eggs are collected and subjected for incubation.

2. Incubation of Eggs:

Eggs of the silk worms called silk-seeds are incubated to obtain the larvae. The eggs are subjected to incubation after assuring the availability of mulberry leaves. Normally incubation is resorted to when the mulberry buds are breaking into leaf.

Incubators are utilized to provide the optimum temperature and to regulate the hatching of the eggs. Further it helps in mass scale hatching of eggs simultaneously, which is highly economical. The eggs are spread evenly in a tray and placed inside the incubator set at 65 F. The temperature is then slowly by 1 or 2° daily. At 77°F the eggs hatch.

3. Rearing of Larvae:

Utmost clean lines and hygiene should be maintained while handling the larvae as they are easily vulnerable to infection. The incubator tray containing just hatched out larvae is taken and covered with perforated paper. Tender and finally cut pieces of mulberry leaves are placed over the paper.

The young larvae wriggle out through the pores on the paper and begin feeding on the leaves. Rearing is done in a special room or cabin and the temperature is maintained at 77°F. The larvae are transferred to large wire meshes covered with paper. Along with their increase in size the number of larvae in each tray is reduced to prevent overcrowding.

They feed voraciously and in 4 to 5 days their size double. The feeding phase (larval phase) lasts for about 40 days during which it passes through 4 periods of sleep alternating with 4 moulting stages. During each moulting the old skin of the larva is shed and a new one formed from beneath.

4. Production and Recovery of Cocoon:

The fully grown larva exhibits signs to indicate that it is about to begin spinning of cocoon. It lifts its front part of the body and moves it in a circular fashion. Close observation has to be maintained to notice this change. They are now transferred to spinning trays containing dry leaves, twigs and straws.

The caterpillar will release its silk secretion from the silk gland and be gains spinning the silk cocoon around itself. Here again, overcrowding must be prevented, otherwise silk threads of two nearby larvae may get entangled and spoil the fibre. In about 9-11 days the spinning will be completed and the cocoons are collected. The cocoons may be preserved immediately after the spinning is over or else, the chrysalis (pupa) moulted inside may cut the exit hole on the cocoon, which spoils the silk fibre.

The cocoons are suffocated by using steam. They are collected over porous trays and placed over a cauldron containing boiling water. The steam will percolate through the pores of the tray and kill the chrysalis inside the cocoon. The treated cocoons can be stocked for weeks in dry places. The chrysalis dead inside will dry up.

5. Spinning of Cocoons:

This is the period when the caterpillar stops feeding and starts to secrete a pasty substance from the silk gland. In this condition worms should be picked up and transferred to the spinning trays and kept in a position of slope (slanting) to the sun for a short period. Within three days spinning is over and the cocoon is formed and this is the last phase of the rearing of silkworm.

Quality of Cocoon:

The quality of cocoon is dependent on the raw silk yield, filament length, and reel ability and splitting.

Marketing of Cocoon:

The price of cocoon is fixed during every season of the rearing. This price is, however, watched by the Government and cocoons are purchased by the rears.

Post-Cocoon Processing:

The method of obtaining silk thread from cocoon is known as post-cocoon processing.

This includes stifling and reeling:

1. Stifling:

The process of killing the cocoons is termed as stifling. Seri-culturists should be very much careful that before the emergence of silk worm (The cocoons which do not have cut holes) good sized cocoons of 8 to 10 days old are selected for further processing and dropped into hot water or subjected to steam or dry heat, sun exposure for 3 days or fumigation. In this way pupae or cocoons are killed. The killing of the cocoon in boiling water helps in softening the adhesion of the silk threads among themselves and loosening of the outer threads to separate freely, facilitating the unbinding of silk threads.

2. Reeling and Spinning:

The process of removing the threads from the killed cocoon is called as reeling. Four or five free ends of the threads of these cocoons are passed through eyelets and guides to twist into one thread and wound round a large wheel from which it is transferred to spools. Thus the silk obtained on the spool is called as Raw silk or reeled silk. The waste outer layer or damaged cocoons and threads are separated, teased and then the filaments are spun. This spunned silk is called as ‘spun silk.’

The raw silk is further boiled, stretched and purified by acid or by fermentation and then carefully washed over again and again to bring about the well-known lustre on the thread.

The modernization of the reeling and spinning process by autolization and various labour saving process has opened a new way to this cottage industry in the world. One autolizer can yield 3.715 kg silk per basin in 8 hours in Japan.

Precautions:

1. Utmost cleanliness and hygiene has to be maintained during sericulture, especially while handling eggs and larvae which are easily prone to infection.

2. Incubation of eggs has many advantages that it helps in simultaneous hatching of eggs, and completion of larval growth, and simultaneous cocoon spinning by the larvae which are useful and economical to the cultivator.

3. Food resource or availability of plant leaves must be assured before beginning the larval rearing.

4. Overcrowding of larvae must be prevented.

5. During diapause and moulting the caterpillars should not be disturbed, which otherwise may lead to death of the worms,

6. The feed leaves should always be maintained moist.

7. Constant inspection of the eggs and larvae for any microbial infection should be carried out. Infected eggs and larvae are to be immediately removed from the culture rooms.

8. Only uncut and complete cocoon shall be used for reeling silk.

Essay # 5. Silk Production in India:

India is holding the 5th position among other nations producing silk. India’s output account for 5% of the total world production of mulberry silk and 10% of tasar silk. India produced 5,200 tonnes of raw silk during 1978-79 out of which mulberry silk constituted 4600 tonnes, and non-mulberry silk 600, tones. The value estimated for the silk produced in approximately Rs. 120 crores per annum. Many states in India are now seriously engaged in silk production viz., in descending order of production.

Status Karnataka, West Bengal ,Jammu and Kashmir, Assam, Bihar, Orissa, Madhya Pradesh, Uttar Pradesh, Tamil Nadu, Punjab and Maharashtra. Karnataka state along contributes 78% of the total silk production. India is exporting about 1/6th of her silk products to foreign countries earning valuable foreign exchange.

The Govt., of India has constituted a ‘Central Silk Board’ to protect the interests of the silk industry. There are many research institutes solely engaged in the R and D projects of silk cultivation and production.

The major ones are:

(1) Central sericulture research Institute, West Bengal, and

(2) Sericulture Research Institute, Mysore.