In this article we will discuss about the Nutritional and Feed Development in Fishes:- 1. The Concept of Feeding Fishes 2. Feed Requirements 3. Live Food of Fishes 4. Supplementary Feeding and Processed Feed 5. Feed Dispensing Methods.

The growth and activity of fishes depend upon the food it takes, not only on the quantity but also on the quality and size of the food object. Thus, fish nutrition is of great significance in fish farming, particularly in intensive culture.

Fishes do not spend energy on maintaining body temperature (poikilotherms) and in the maintenance of its position in water. The diet it takes is used in protein building material and energy requirement for metabolic activity. A deficient diet may cause nutritional diseases and other disorders that would adversely affect its growth.

Traditional aquaculturists depend totally on the production of natural food through the use of fertilisers and pond management. This practice, to some extent, is followed in extensive and semi-intensive farming. However, they resort to supplementary feeding to ensure adequate availability of food in dense stocking and for enhancing growth and production.

The Concept of Feeding Fishes:

ADVERTISEMENTS:

(a) Classification of Various Stages of Aqua-culture:

Depending on the quantity and quality of nutrients utilised by the aquaculturist, the levels of aquaculture are:

(i) Extensive — no nutrients added.

(ii) Fertilisation — feed given to enhance production of aquatic organisms.

ADVERTISEMENTS:

(iii) Supplemental feeding — incomplete feed given.

(iv) Intensive feeding—nutritionally balanced feed.

(v) Hyperintensive feeding—High inputs of concentrated nutritionally complete feeds.

(b) Fish Production Exclusively from Natural Aquatic Food:

ADVERTISEMENTS:

Some fishes are planktivorous. They obtain their food exclusively from plankton. These fishes are usually grazers and have mechanism for filtering and concentrating the suspended plant and animal organisms from the water.

Example of such types are catla, rohu, silver carp, etc. Tilapia, on the other hand, has the ability to feed both on plankton and on bottom materials. Mrigal is an efficient bottom feeder, while grass carp consumes large quantities of aquatic weeds. Such fishes can be cultured without artificial feeds, but usually with application of fertilisers.

(c) Supplemental Feeding:

In this case along with natural food, various feedstuffs or prepared feeds are used as a supplement to increase fish yield.

In prawn culture the impoundment is first fertilised to enhance natural productivity and in addition pelleted feeds are also given. This increases the yield of prawns. Supplemental feeding is used where natural aquatic food makes small contribution to the total protein and energy requirement of the cultured fish.

(d) Intensive and Hyperintensive Feeding:

In these system of culture, natural foods are an insignificant source of nutrients. Here, primary concerns are minimum accumulation of unretained nutrients and obtaining maximum yield per unit space and effort. Thus, such a culture needs highly concentrated, nutritionally complete feed.

(e) Nutrient Requirement:

Like any other animals, fishes require nutrients for growth, reproduction and other normal physiological functions. Fishes have dietary requirements for the same 10 essential amino acids like mammals.

ADVERTISEMENTS:

However,

(i) The energy requirements are lower for fishes,

(ii) Fishes require some lipids such as omega-3 (n-3) series of fatty acids and sterol,

(iii) Fishes have the ability to absorb soluble minerals from the water and

(iv) Most fishes have limited ability to synthesise ascorbic acid and thus, depend upon dietary sources.

Nutritional requirements do not vary greatly among different species of fishes. However, the nutritional requirements have been derived from experimentation upon a few species that have served adequately for the nutrient needs of others. Similarly, the ration yielding the best growth and yield has been assumed to be the most satisfactory feed for that species.

(f) Feeding Practices:

As fishes are fed in water, it may so happen that a substantial amount of feed may remain unconsumed. Such happening may not only result in economic loss but also can reduce the water quality. Therefore, the aquaculturists must consider factors such as feed allowance, feeding method and water stability.

(g) Efficiency:

The efficiency of conversion of feed into body tissue has been found to be more efficient in fishes than in land animals. The reason for this is that the fishes are able to assimilate diets with higher percentage of protein, probably due to their lower dietary energy requirement.

This lower energy requirement is due to a lower maintenance requirement and lower heat increment. Thus, fishes have a lower energy cost of protein gain, rather than superior food conversion efficiency. The food conversion rate is the weight increase relative to the amount of food (which is given). It expresses the ratio between the food consumed per unit weight gained by the body.

The food conversion rate is also denoted as food quotient, food coefficient, growth coefficient, etc.

Feed Requirements:

(a) Bioenergetics:

Energy is not a nutrient. Energy is released during metabolic oxidation of carbohydrates, fats and proteins (amino acids). Bioenergetics or nutritional energetics is the study of the balance between energy intake (in the form of food) and energy utilisation by animals for life-sustaining processes such as tissue synthesis, various activity and self-maintenance.

For productive purposes, the difference between gross energy and energy available to the animal, varies widely among food materials. Digestibility accounts for most of the differences in available energy among feedstuffs for fishes.

(b) Energy Balance:

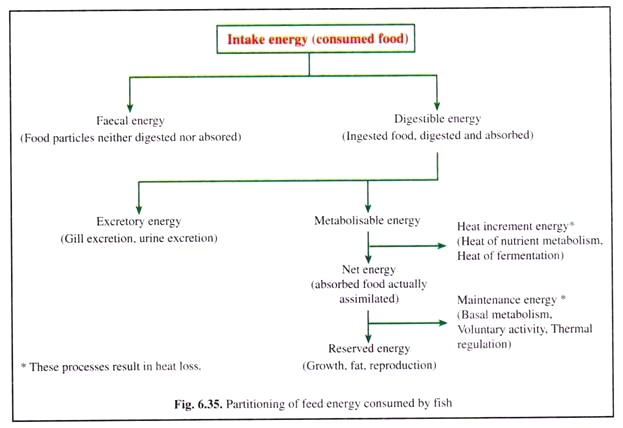

The fate of energy balance in fishes is given in Fig. 6.35. There are two types of energy generally witnessed — heat energy that is lost for maintaining body temperature and the free energy utilised for growth and biological activities. The latter one is more important for fishes as they are poikilotherm animals.

Energy metabolism in fishes, like other cold-blooded animals, is different from warm-blooded animals in that they do not expend energy to maintain their body temperature, different from its environment. In fishes, the excretion of waste nitrogen requires less energy as they can be readily released into the water through the gills.

The metabolic rate in fish is dependent upon temperature, age or size, activity and seasonal and diurnal fluctuations of body functions. It is also influenced by oxygen or carbondioxide concentration, pH and salinity of the water. Of the total energy utilised by carps (calculated to be 25 cal/dec2/h at 25°C), about 70 per cent is used for maintenance and growth and the remaining 30 per cent is lost to the environment.

As is shown in Fig. 6.35, heat losses occur mainly by two ways:

(a) heat increment that includes energy cost of digestion, nutrient metabolism and excretion and

(b) maintenance energy represented by basal metabolism (such as respiration, transport of ions and metabolites) and voluntary activity. In fishes, the maintenance energy requirement is lower, which means a greater per cent of the net energy is not dissipated as heat but retained within the body of fishes as new tissue or recovered energy.

(c) Energy Requirements and Sources:

As fishes live in an aquous environment, where carbohydrates are rare, their digestive and metabolic systems are better adapted for the utilisation of protein and lipids as sources of energy than carbohydrates. Even in some fishes like grass carp, that consume macro- phytes (higher aquatic plants), their digestion of native cellulose is poor.

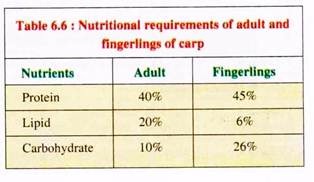

The energy requirements of fishes are generally supplied by carbohydrates, proteins, lipids, vitamins and minerals for maintenance of growth. Most of the available information on energy requirements have been derived primarily from experimentation. On an average the various requirements of the carps are given in Table 6.6.

(i) Protein:

In fishes protein has a metabolisable energy value of about 4.5 kcal/g, which is comparatively higher than that of mammals and birds. Fishes among all animals are the most efficient in converting feed energy into high quality protein. Fishes require the same 10 Essential Amino Acids (EAA) as other animals. Diet deficient in any of the EAA leads to depressed appetite and reduced weight gain.

(ii) Lipid:

Lipids or fats are the fatty acid esters of glycerol. The Poly-Unsaturated Fatty Acids (PUFA) requirements in fishes are found to be significant in the diets. In carps the lipid requirement is about 4-6 per cent in the diet. Most commercial aquaculture diets have less than 10 per cent of lipid. High lipid levels may lead to fatty liver disease or cause greater deposition of visceral fat.

(iii) Carbohydrate:

Carbohydrates, in animal aquaculture, are the most abundant but relatively least expensive source of energy. Adult stages of carps utilise less carbohydrates (about 10 per cent) than fry or fingerling (about 26 per cent) stages. Although common carp utilises higher levels of carbohydrates, their diets contain over 40% dextrin that results in retarded growth.

Successful fish feed contains a certain amount of carbohydrate — 20 per cent for cold-water and 30 per cent for warm-water fish feed. Carbohydrates, in addition, have the physical function of texturizing manufactured feed and also help as a binder in the formulation of pellets.

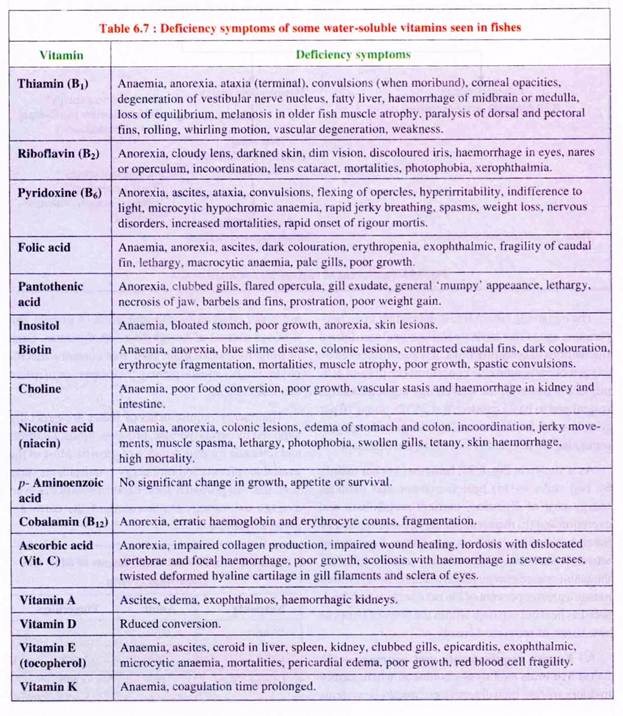

(iv) Vitamins:

Vitamin requirements of fishes are derived from the natural food. In prepared feeds adequate quantity of vitamins is generally added. However, excess of vitamin A may cause enlargement of liver and spleen, abnormal growth of bone formation and epithelial keritonisation. For water soluble vitamins, some of the deficiency symptoms observed is given in Table 6.7.

(v) Minerals:

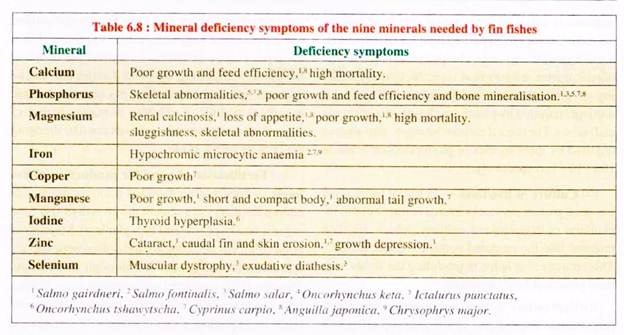

Fishes, like all animals, require minerals for various biological functions such as formation of skeletal tissue, blood plasma, haemoglobin formation and also for many enzymatic reactions.

Of the twenty six naturally occurring essential elements required by animals, only nine have been seen to be needed by fin fishes. The deficiency symptoms of these minerals are shown in Table 6.8. Water generally contains an abundance of minerals, so supplementation in diets is generally not needed.

Live Food of Fishes:

(a) Natural Sources of Live Food:

Most aquatic animals subsist on live food comprising of both plants and animals. These they obtain from the environment in which they live. Some, however, ingest and utilises detritus along with associated benthus organisms. All these foods are generally rich in essential nutrients.

Larval stages of many fin fishes and crustaceans depend entirely on live food, and their initial source of food is phytoplankton (probably associated with the size of the larvae at hatching). After the larvae have developed to a certain length they feed exclusively on either zooplankton or other animal species or on a combination of plant and animal matter.

For hatchery use, it is more convenient to culture algae under controlled conditions. In nursery and grow-out ponds, live food are generally produced as a result of the biological cycle initiated by mineral nutrients in solution.

Light penetration is an important factor, as the sun’s heat and light is used to convert the inorganic matter and carbonic acid in solution into organic matter, in the form of vegetable tissues consisting of phytoplankton and periphyton.

The major nutrients required by plants are phosphorus, nitrogen and carbon. The ratio of carbon: nitrogen: phosphorus required by most species of phytoplankton is about 106: 16: 1, respectively.

(b) Culture of Live Food:

In recent times there has been greater interest in intensive forms of phytoplankton or zooplankton cultures, which are then released into the prepared ponds for multiplication. This strategy also helps in providing the fishes with their preferred food organisms.

(i) Algal Culture:

Now-a-days algal culture facilities form an integral part of many shrimp and prawn hatcheries. The most important activity of algal culture is seen in controlled breeding of molluscs (oysters), where they are used to feed the larvae.

Various species of microalgae are cultured in laboratories for experimental uses or in special tanks for commercial purposes. In some centres of Macro – brachium culture, a “Green Water Method” of algal production is generally practised. Green water is a mixed phytoplankton culture, with a pre-dominance of Chlorella sp.

(ii) Zooplankton Culture:

Zooplanktonic organisms can be obtained either by collection from natural waters or by culture under controlled conditions. Small-scale collection of zooplankton from natural waters using standard plankton game is common, but large-scale plankton collection is practised rarely either by use of two cone type of net or by phototactic reaction using underwater lights to attract plankton.

However, there are many uncertainties in the quality and quantity of plankton that can be obtained. So, for using in hatchery production of larvae, it is advisable to depend upon culturing of plankton.

Besides, the culture of Rotiferans (Brachionus, Filinia, Keratella, etc), Cladocerans (Daphnia, Moina, etc.), Copepods (Cyclops, Diaptomus, etc.), cultures can also be done of Oligochaetes (earthworm, Tubifex) and chironomid larvae. Flat trays filled with manured soil and covered with water attract chironomid flies to deposit eggs in them. A production of about 0.3 kg/m2/week can be obtained. Tubifex also can be cultured by using sewage and pig or horse manure as culture medium. It develops in masses within 15 days of innoculation and can be obtained by dredging the bottom with a spade.

(c) Fertilisation of Pond for Production of Live Foods:

Pond management has led to the practice of adding fertilisers to augment the growth of fish food organisms like phyto- and zoo- plankton. Majority of pond culture of herbivorous and omnivorous species is based on food production through fertilisation.

Sometimes it is combined with supplementary feeding with easily available foodstuffs. In India, the priority is always to produce fishes to support the low income population. So, use of supplementary feed is not feasible as it would increase the cost of the fishes.

Secondly, manufacture of aquaculture feeds in India is not well-developed and thirdly, the design and operation of pond farms are best suited for the growth of natural food organisms. The fertilisers used in aquaculture are organic and inorganic in nature or a combination of both types. Details of such fertilizers and their application is given in page 254.

Supplementary Feeding and Processed Feed:

(a) Supplementary Feed Ingredients:

In traditional aquaculture, various feedstuffs have been used from time to time. It comprises oil cakes, wheat and rice bran, mill waste, brewery wastes, slaughterhouse wastes (blood, etc.), bean residues, silkworm pupae, poultry wastes, fish offal, trash fish, fish byproducts, etc. These feedstuffs in various combinations are provided as mixtures in order to improve the food conversion ratio.

Besides the above mentioned feedstuffs, processed compound feeds are also used to supplement natural food. Such formulated feeds are generally aimed at providing additional protein and fat. But the feeding cost amounts to 40-60 per cent of the overall cost of production, mostly in intensive aquaculture where complete feeds are used.

However, the cost of production can be reduced if less expensive supplementary feeds are used in combination with natural food. The composition and quantity of feeds to be used is based entirely on field trials and experience of the farmer.

Various feed ingredients and their composition are as follows:

(i) Primary Plant Protein Sources:

(1) Soybean Meal:

After removal of the oil from soybeans, the residue is soybean meal. It is of three types — dehulled and solvent extracted, solvent extracted and expeller extracted containing 48%, 44% and 42% protein, respectively. Soybean meal is highly palatable to most warm-water fishes and is the major protein source used in aquaculture feed containing all essential amino acids.

(2) Cottonseed Meal:

It is obtained by grinding the cake, the remains after extraction of the oil. Cottonseed meal contains about 41% protein but is deficient in lysine. It is generally used in preparing catfish feeds at a level of 10 to 15% of the total feed.

(3) Peanut Meal:

After the peanuts are grinded and the oil extracted (mechanically or by solvent extraction), the peanut meal is obtained. Mechanically extracted and solvent extracted peanut meal contains about 45% and 48% protein, respectively. Although they are highly palatable to fishes they are seriously deficient in lysine.

(4) Sunflower Meal:

Sunflower meal is obtained after extraction of the oil from the sunflower seeds. It contains about 44% protein. However, its low lysine content and high level of fibre (13%), limits its usefulness as fish feed.

(5) Canola Meal:

It is prepared from a special rapeseed after the removal of oil. It contains about 38% protein, but relatively low in lysine, Canola meal is low in glucosinolates and erucic acid which is considered detrimental to fish growth. However, it can be used up to a level of 20-25% in fish feeds.

(ii) Primary Animal Protein Source:

(1) Fish Meal:

Fish meal contains 60 to 80% excellent quality protein and is a good source of essential amino acids. It is also rich in energy, minerals, vitamins and essential fatty acids. However, it is used sparingly for preparation of many commercial fish feed due to its high cost.

(2) Fish Soluble:

Fish soluble is obtained after extraction of fish body and liver oil. It contains about 50% dry matter, 30% protein and 4% fat.

(3) Meat and Bone Meal:

It is the rendered product from beef or pork tissue, but should not contain other materials such as hoof, hair, horn, hide, blood, intestine, etc. It contains about 50% crude protein and is a good source of minerals.

(4) Blood Meal:

Blood meal is a by-product from the meat packing plants and consists of clean, fresh animal blood. The protein percentage in blood meal is 80 to 86%. It is rich in lysine but deficient in methionine.

(5) Poultry By-Product Meal:

It is made up of grounded carcass of slaughtered poultry comprising head, feet, undeveloped eggs and visceral organs. However, it does not contain feathers. This product contains good quality of 59% protein.

(6) Poultry Feathers, Hydrolysed:

The clean, undecomposed feathers from slaughtered poultry is subjected to high pressure treatment to produce hydrolysed poultry feathers. Although its protein percentage is high (85%), the quality of the protein, however, is poor as it is deficient in several essential amino acids, particularly lysine.

(7) Shrimp Waste Meal:

Shrimp waste meal is prepared from the discarded head, limbs and exoskeleton. The exoskeleton is primarily chitin and has limited nutritional value. Shrimp waste meat contains 40% crude protein and is a good source of fatty acids, cholesterol (essential for crustaceans) and astaxanthin.

(iii) Energy Supplements:

Energy supplements are those feedstuffs that contain less than 20% protein.

These include:

(1) Corn Products:

Grounded corn grain and corn screenings are used as a relatively inexpensive source of energy to feed commercial catfishes. Cooking the grains and screenings improve the digestibility of corn for fish. Corn products up to 45% have been used in warm-water fish feeds without any adverse effects.

(2) Sorghum:

In sorghum grains the nutrient composition is similar to corn but the protein content is slightly higher (11%).

(3) Rice Products:

Rice bran is high in fat and fibre. This limits its used in fish feeds to less than 7%.

(4) Wheat Products:

Wheat grain is a good pellet binder, but is generally more expensive than corn. It is a good source of energy for warm-water fishes. Wheat products when used primarily as binder, a quantity of 2-5% is generally used.

(5) Animal and Plant Fats and Oils:

They are highly concentrated source of energy and acts as a source of essential fatty acids. Animal fats and oils are generally preferred over plant oils as they are less expensive.

(iv) Vitamins and Minerals:

Although most commercial feedstuffs used in preparing fish-feeds contain vitamins and minerals, still the fish-feeds are supplemented with vitamins and trace minerals as well as phosphorus.

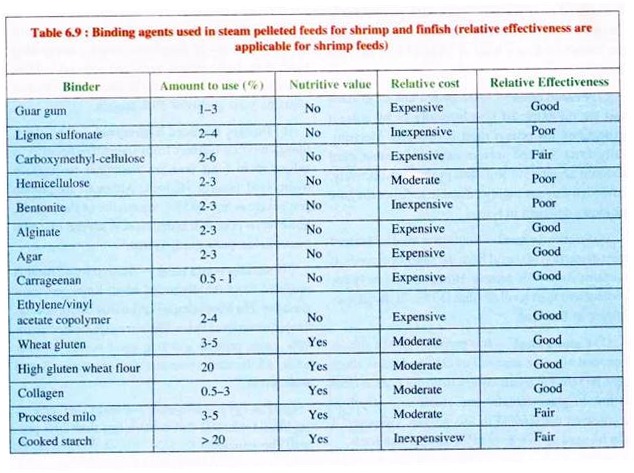

(v) Binding Agents:

Binding agents (Table 6.9) are generally much in use for steam-pelleted crustacean feeds, which must remain stable in water for several hours. The stability of steam-pelleted feeds in water is dependent on the amount and type of binder used. Wheat flour and high-gluten are of common use as binder for srimp feed as it is cost effective.

(b) Feed Formulation:

The nutrient content of feed may vary according to the maturity and processing of feed materials and also in relation to their protein fibre and ash content. While formulating feed, it is essential to check the Essential Amino Acid (EAA) levels in the ingredients.

Fish meal is widely used as one of the ingredients as it is a good source of EAA and EFA (Essential Fatty Acid). However, due to the increased cost of fish meal suitable alternatives like oil-cakes and soybean are being used, although soybean has been found to produce reduced growth rate as compared to fish meal.

The main objective of feed formulation is to provide a diet that meets the nutritional requirements at different stages of life, so as to yield optimum production at minimum cost. While trying to keep the cost at minimum it should be seen that no compromise is done with the quality of the nutrient content.

The formulation of feed is also dependent upon the type of culture system. Semi-intensive culture does not require vitamin and mineral supplements, as these nutrients can be obtained by the fish from the natural food organisms present in the pond water. In intensive culture, on the other hand, natural foods are limited and their diet should contain all the required nutrients in adequate quantities and proportion.

Computation of protein in diet formulation — In animal diet, protein is the most expensive ingredient. In diet formulation, it is first computed and is done generally by two methods — (i) Square method and (ii) Algebraic equations.

Problem 1:

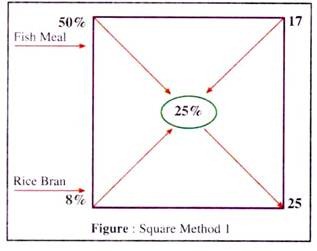

In a supplementary feed 25% protein is desired using fish meal (50% protein) and rice bran (8.0% protein).

Solving by the Square Method:

Calculation can be done by both percentage basis and as ratio. For this a square is constructed as shown in figure Square Method 1.

In the above square the desired protein level (25%) is placed at the centre and two feedstuffs with their protein percentages (50% and 8%) are placed on the left-side corners of the square.

Then, the protein levels of each feedstuff are subtracted from the desired protein level of the feed to obtain 25-50 = -25 and 25-8 = +17, respectively. The differences thus obtained (25and 17) are placed on the corners of the square diagonally opposite to the feedstuff ignoring the ‘+’ and signs.

The proportion of fish meal needed in the feed can be computed by the difference between the percentages of protein in the rice bran and the protein required in the feed. Similarly, the proportion of rice bran required is the difference between the protein percentages of fish meal and the feed being formulated. The ratio thus obtained is 17 parts fish meal: 25 parts rice bran.

The value can also be calculated on percentage basis by the following way:

(i) The difference of percentage in the two feeds are 50-8 = 42. The figure ’42’ can also be obtained by adding the values on the right-hand corners of the above square: 25+17 = 42.

(ii) The percentage of fish meal required is

17/42 x 100 = 40.48% 42

Similarly, the percentage of rice bran required is

25/42 X 100 -59.52% 42

(iii) Thus, to prepare a balanced supplementary feed containing 25% protein, the proportions required are 40.47% fish meal and 59.52% rice bran.

Solving by the algebraic method:

Suppose,

x = fish meal in kg/100 kg feed

y = rice bran in kg/100 kg feed

X + Y = 100 kg feed (1)

Taking the protein into account, we get

0.50x + 0.08y = 25 kg protein/100 kg feed (2)

Multiplying equation (1) by 0.08, we get

0.08x + 0.08y = 8. (3)

By subtracting equation (3) from (2), we get

0.42 x = 17.

... x = 17/0.42 = 40.48 kg/100 kg feed.

... fish meal required is 40.48%.

Similarly, for calculating the requirement of rice bran,

y = 100 – x

or, y = 100 – 40.48 = 59.52 kg/100 kg feed,

... rice bran required is 59.52%.

Problem 2:

In actual practice more than 2 ingredients are used for feed formulation.

As for example:

A 30% protein level is required using the following mixture:

Fish meal 60% protein

Soybean 51% protein

Rice bran 8% protein

Corn meal 10% protein

The above ingredients are used in the following proportions:

2 parts soybean: 1 part fish meal

1 part rice bran: 1 part corn meal

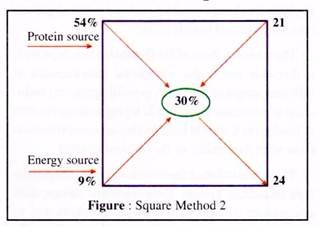

Solving by the square method (2):

The desired protein level (30%) is placed at the centre of the square.

The ingredients are divided into 2 groups—protein source and energy source.

The protein level of each group is calculated by the following way:

Protein Source:

The proportions given in the question is

2 parts soybean: 1 part fish meal

... fish meal = 1 x 60 = 60%

Soybean meal = 2×51 = 102%

The average protein source = 162/3 = 54%.

Energy Source:

The proportion given in the question is

1 part rice bran: 1 part corn meal

... rice bran =1 x 8 = 8% Corn meal = 1 x 10= 10%.

The average energy source = 18/2 = 9%.

The protein and energy source along with their calculated values of 54 and 9, respectively, are placed on the left- hand corners of the square. After diagonal subtraction the values 21(30-9) and 24 (30-54) are placed on the right side at the two corners of the square.

The difference of percentage of protein source and energy source are obtained by either

54-9 = 45

or, 21 +24 = 45.

The percentage of protein source would thus be:

21/45 x 100= 46.67% 45

and similarly the percentage of energy source would be:

24/45 x 100 = 53.33%

In the protein source 2 parts soybean meal and 1 part fish meal were used. So, the protein source was made up of 2/3 soybean and 1/3 fish meal.

Total protein source was calculated to be 44.67%, which comprises:

Fish meal = 1/3 x 46.67 = 15.56%

Soybean meal = 2/3 x 46.67 = 31.11%.

Similarly, the energy source of 53.33% is comprised of 1 part rice bran and 1 part corn meal which is calculated to be:

Rice bran = 53.33/2 = 26.665%

Corn meal = 53.33/2 = 26.665%

Solving by the Algebraic Method:

Suppose:

x = protein source in kg/100 kg feed

y = energy source in kg/100 kg feed

x + y = 100 kg feed. (1)

0.54x + 0.09y = 30 kg protein/100 kg feed. (2)

By multiplying equation (1) with 0.9, we get 0.09x + 0.09y = 9. (3)

By subtracting equation (3) from (2), we get 0.45x = 21.

... X = 21/6.45 =46.67%

Fish meal = 46.67 x 1/3 = 16.56%

Soybean meal = 46.67 x 2/3 = 31.11%.

From equation (1), we have y = 100-x

... y= 100-46.67 = 53.33%.

... rice bran = 53.33/2 = 26.665%

Corn meal = 53.33/2 = 26.665%.

(c) Types of Processed Feed:

Processed feed ensures that the cultured animal receives a balanced diet that meets their nutritional requirements. Processed feed also ensures the quality and availability of food. These feeds are formulated according to nutrient specifications and are usually expensive than supplementary diets.

(1) From compositional point of view three types of processed feeds are recognized:

(i) Purified,

(ii) Semi-purified, and

(iii) Practical.

(i) Purified Feed:

Such diets are made of synthetic amino acids, fatty acids, carbohydrates and chemically pure vitamins and minerals. Purified feeds are comparatively expensive. They are used only for research purpose.

(ii) Semi-Purified Feed:

Such diets are made of natural ingredients in pure forms as much as are available (example: casein, fish oil, corn oil, etc.). Semi- purified feeds are commonly used in nutritional studies as test diets to determine the efficiency of different levels of dietary components in terms of food conversion or growth.

(iii) Practical Feed:

Such diets are made up of available ingredients and to a large extent natural products such as fish meals, oil seed meals, cereal grains, etc. Practical diets are aimed at keeping the cost of feed at the minimum.

(2) Based on water content artificial compound feeds can be classified into:

(i) Moist feed and

(ii) Dry feed.

(i) Moist or Wet Feed:

Such feeds are prepared without exposure to heat such that it does not result in nutritional losses. Grinding and mixing machines are only used. Moist feeds are used for practical or test diets. Species fed on moist diet show better feed conversion ratios and growth.

Such diets are to be used immediately after preparation as they are susceptible to spoilage. Otherwise freezing is required to prevent spoilage by micro-organisms and deterioration of oxygen-sensitive nutrients, such as ascorbic acid.

(ii) Dry Feed:

Dry feed contains only about 8-11 per cent water and are relatively more water stable. The water stability of such feeds can be adjusted to suit the feeding habits of the cultured species by using appropriate binders and processing techniques.

Similarly, by using extrusion techniques of processing, the density of the pellets can be adjusted to make them float or sink in water. Dry feeds have the advantage of easy storage and transport. Different sizes and shapes of pellets with different nutrient compositions are easily adjusted by the use of suitable diets. These are needed to feed successive growth stages of a species.

For feeding of newly hatched larvae, the sizes vary from finely ground granules to encapsulated forms, while from small pellets to larger pellets of about 1 cm diameter and 1.5 cm length are used to feed the adult fishes. The composition of the feed is thus related to the nutrient requirement of each life stage. For example, specially made high protein diets are used to feed the brood fishes.

(3) There are various specialised feeds that are in use, such as:

(i) Larval Feeds:

Newly hatched larvae of fin fishes and prawn depend on live food such as unicellular algae, rotifers and nauplii of brine shrimp for better survival. Use of prepared feeds has been successful for some species. As cultured live foods (phytoplankton, zooplankton, etc.) are expensive, larval feeds have been developed to replace them.

However, such larval feeds used to feed larval fishes in the hatchery should be less than 0.5 mm in size, palatable, water stable and nutritionally complete.

(ii) Meals and Crumbles:

These feeds are used for feeding fish fry and small fingerlings and have small particle size. Meal type feed is generally prepared by reducing the particle size through grinding and screening to a particle size of not more than 0.5 mm and mixing the ground ingredients. Crumbles are formed by crumbling pelleted feeds and then screening to appropriate size.

(iii) Microencapsulated Feeds:

Small particles or beadlet of feed when coated with a thin layer by a compound which will reduce the dissolving and leaching of nutrients, are called microencapsulate feed. Several patented processes for microencapsulation of larval feeds are in use such as nylon (N-N bonds) cross-linked proteins, calcium alginate and lipids. These materials should be non-toxic, water insoluble and easily digestible by the fish larvae.

(iv) Flaked Feeds:

For aquarium fishes feed should be nutritionally complete, palatable, should float or sink slowly and should not disintegrate quickly in water. The ingredients are first ground to fine particle size with an attrition mill and blended with water to form a sludge that is spread evenly over the surface of a heated rotating drum, so as to dry it into a thin sheet.

The dried sheet is then continuously scrapped off from the rotating drum and crumbled into flakes. Flakes contain ingredients with good hydrocolloidal properties and also good tensil strength.

(v) Medicated Feeds:

Medicated feeds contain antibiotics. There are two such antibiotics, Tetramycin (oxytetracycline) and Romet (sulfadimethoxine-ormetoprim), that are available commercially. Tetramycin is used in steam pelleted feeds as it is heat sensitive and destroyed during extrusion. On the other hand romet is heat stable and can be used in extruded feeds. Mills preparing such feeds should be licensed to add these antibiotics to their feed.

(vi) Crustacean Feeds:

As crustaceans are bottom feeders, they require diets that will remain stable in water for a longer period of time and will not float. Feedstuffs with good binding properties along with special binding agents should be used in steam pelleted feeds. Thus, binding agents are important for water stability of the feeds.

(d) Feed Preparation:

Although specialised aquaculture feed mills are increasing steadily yet there are large areas that are not yet served by commercial feed milling for aquaculture. In such cases aquaculturists will have to resort to on-farm production of feeds, on a small scale. The first pelleted carp feed in India was prepared at Freshwater Aquaculture Research and Training Centre (FARTC), at Bhubaneswar in 1982.

(i) Small Scale Production:

Feeds can be produced in the farm using inexpensive equipment and locally available ingredients. The equipments include weighing machines, sieves, mixer (small, of 5-10 kg capacity), meat grinder, corn meal or coffee grinder, a steamer and bamboo basket for steaming, a saucepan for gelatinising starch and a drier.

The locally available ingredients, in the relevant formula are finely ground and passed through a sieve. It is then weighed and mixed thoroughly. Oil is then added and mixed again for a few minutes. The starch, gelatinised with water, is then mixed thoroughly with the mixture, until it forms a dough.

This dough is then passed through a grinder using a 1-3 mm die. The feed that extrudes out is cut into small sizes (about 0.5 cm) and then steamed to make water-stable pellets. The steamed product is then placed on an oven and dried overnight at 60°C. Such pelleted feed is made once a week as per the need of the farm.

(ii) Large Scale Production:

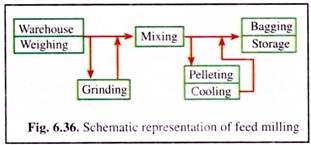

For requirement of feed in large-scale, the method described above is not feasible. Large-scale milling is necessary, although the basic process involved is essentially the same. It also consists of particle size reduction, premixing of micro-nutrients, mixing of all components of the diet, pelleting, cooling and then sacking (Fig. 6.36).

(1) Grinding:

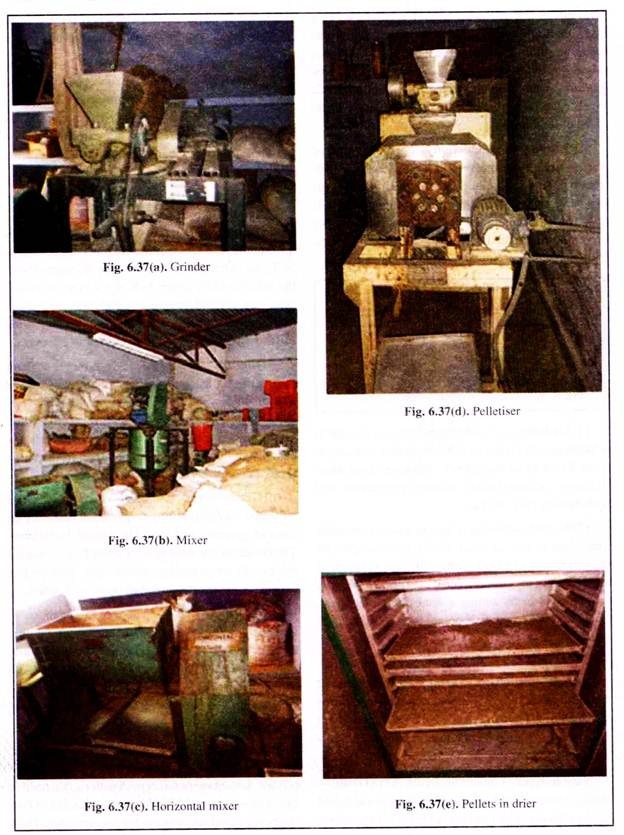

Coarse ingredients are ground in a hammer mill. Grinding reduces particle size, facilitates handling of ingredients, improves feed digestibility, acceptability, mixing properties and pelletability (Fig. 6.37a).

(2) Sieving:

Sieving is done to separate materials into sizes as per the need. Feeds, for example, are passed through 177 µm meshes. If there is excess of dust entering the grinder, then it may be controlled by sparying oil or by adding a semi-moist ingredient, such as condensed fish solubles or fermentation solubles.

(3) Mixing:

Mixing is done to achieve uniformity of composition in the whole feed material as per the required formula. It involves scattering of particles and blending. For formula feed, the technique which is generally adopted is continuous mixing of proportions by weight or volume (Fig. 6.37b) & (Fig. 6.37c).

Various types of mixers are in use in feed mills — vertical mixers, continuous ribbon mixers and liquid mixers. To get proper mixing, addition of ingredients in a tested sequence is required, where large volumes of ingredients are added first, followed by smaller amounts.

(4) Pelleting:

Pelleting involves passing a feed mixture through a conditioning chamber where 5-6 per cent water or steam is added. Water provides lubrication for compression and extrusion. In the presence of heat, raw starch present in the ingredients of plant origin, helps in adhesion (Fig. 6.37d & e).

After entering the pellet mill, the feed is first air- dried and then given 15-16% moisture at 80-90°C. During subsequent compression and extrusion through the die, the feed temperature may increase to nearly 90°C due to friction.

Pellets are then discharged from the pelletizer to a screen belt of a horizontal tunnel drier or a vertical screened hopper. The pellets are then air-cooled in about ten minutes. It is then dried to decrease its moisture content to below 13 percent.

(5) Binders:

When the feed mixture is difficult to pellet or is unstable in water, it is essential to add a binding agent (Table 6.9) to the formulation. Normally starch can act as a binding agent. Other successfully used binding agents include carboxy- methyl cellulose, gelatin, algin (extract from marine algae, Laminariaceae), etc.

(6) Granules and Crumbles:

The cooled pellets are sometimes ground on corrugated rolls into various sizes of granules and crumbles (small fragments). The crumbles are used to feed small fishes, and are more easily consumed by sight-feeders. They are less expensive to manufacture than small size pellets.

(7) Types of Pellet:

Generally two qualities of the pellets are important: hardness and water stability. Hard pellets are special, liked by many species. However, there is always a danger of overfeeding (with hard pellets), which causes swelling and rupture of the stomach. The hard pellets are not digested thoroughly and causes fermentation and gas formation.

Feeds pelleted by the extrusion process forms floating pellets which are suited for certain types of culture. Advantage of this type of pellet is that the fish can be observed while feeding and the amount of feed can be regulated according to the amount eaten.

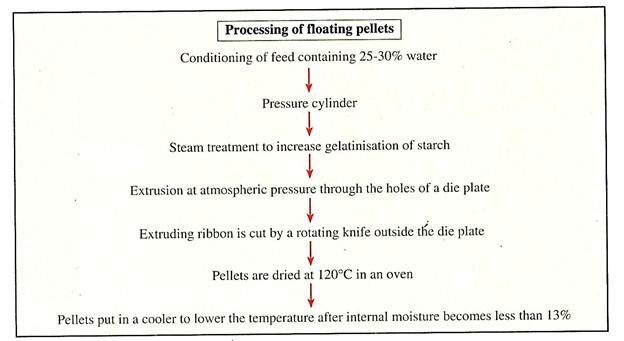

Thus, it improves feed conversion. Floating pellets are processed as follows:

(8) Packing of the Prepared Feed:

The pellets are usually packed in polyethylene-lined sacks made of multilayered paper or other material.

(9) Storage:

Raw materials and processed feeds both should be properly stored to prevent them from deterioration during storage. Loss of raw materials may occur due to insect infestation. Feed materials generally undergo chemical changes that alter their flavour and nutritive value. However, properly stored feed will keep well for 1-3 months in summer and 2-4 months in winter.

In a feed mill, care should be taken to store both feed materials and processed feeds in cool and dry conditions as much as possible. They should be raised off the ground on platforms. Warehouses or silos should be constructed in such a way that the interior remains cool and dry with adequate ventilation.

(10) Contaminating Agents:

Fats in feedstuffs often break down during storage. Rancidity (unpleasant smell or taste) is caused due to oxidation of lipids. Lipid oxidation can be inhibited by the addition of antioxidants such as ethoxyquin, butylated hydroxytoluene (BHT) and butylated hydroxyanisole (BHA).

Recontamination of feedstuffs by micro-organisms is another major hazards. Fungi grow at moisture contents of 15-20% and cause spoilage of feedstuffs in storage. The highly toxic and carcinogenic aflotoxins produced by Aspergillus flavus are one of the most important mycotoxins contaminating feedstuffs.

(11) Finishing Products and Quality Assurance:

The finished products are routinely assayed for moisture, protein, fat and fibre. Selected micronutrients are periodically checked to ensure nutritional quality. Each batch of feed should be checked for physical characteristics, such as pellet stability and floatability. Guaranteed analyses for commercial feeds is required for most states and countries.

(e) Feeding Rates:

Initially the fry (about 0.25g) requires feed as much as 10% of their weight daily. After attaining a weight of about 4 g, the feed is reduced to about 5% of the body weight per day. The total amount of feed to be given is generally estimated by multiplying the weight representing the desired growth by the conversion rate.

Feed conversion ratio = feed intake/weight gain

Feed Dispensing Methods:

(a) Hand-Feeding:

Hand-feeding is the most common method of feed dispensing. Its advantage is that the farmer can observe the feeding behaviour of the stock and ensure that the feed is made available to all the fishes. ‘Disc throwers’ and hand-operated blowers are generally the mechanical aids used for hand feeding. In large fish ponds boats are also used for hand feeding.

(b) Automatic Feeders:

Various types of automatic feeders are used for prepared feeds in larval tanks and grow-out areas.

Electrically-activated timing devices are used to dispense set amount of feed at certain intervals.

The dispersal patterns are of different types:

(1) Feed are dropped directly into the water from storage bin.

(2) Feed may be dispersed widely by falling onto a rotating disc.

In another model, electrical impulses are received by a vibrator present just inside the opening at the bottom of a conical feed hopper. A small plastic disc is present underneath the hopper. Pellets fall onto the disc, which vibrates each time impulses are received and are thrown into the water.

Mobile mechanical feeding systems such as blowers are also used to dispense feed over large areas. Mechanisms using compressed air to distribute pellets over the water have also been successfully used in raceway cultures.

(c) Demand Feeders:

Demand feeders are activated by animals themselves by means of a rod or plate hanging from the feeder into the water. The rod or plate is struck by the moving fish mistaking it as a bait. This results in the release of a small amount of pellet from the hopper. The fish soon learns to activate the feeder and it generally does so when it wishes to feed.

(d) Computer Controlled Feeders:

Computer controlled feeders are used by advanced countries, where the quantity of feed and frequency of feeding are regulated through appropriate programs. It takes into account several variables such as stock density, growth rate, conversion rates, temperature conditions, mortality, harvest time, etc.